All About Chassis

Often overlooked by shiny wedges and horrifying weapons, the chassis of a Battlebot is the bread and butter of how these magnificent beasts are built. They have the responsibility of holding the wheels, electronics, batteries, weapons, and everything else that makes a BattleBot function! The frame also needs to take the abuse of combat — giant shock loads from being smashed around and potentially large weapons ready to chew through your fragile electronics. It should be no surprise that this incredibly important feature of our robot takes hundreds of hours to design!

There are many different ways to construct a combat robot frame. Most notably, you’ve got:

Welded Chassis

Machined & Bolted Chassis

Billet Chassis

Welded Chassis

Arguably the most economical way to construct a chassis, welded frames include pieces of metal, waterjet, laser or plasma cut from a large sheet of metal, and assembled using welding. Materials for these frames are often made out of Abrasion Resistant Steel or Aluminum.

Bite Force was constructed of a welded aluminum frame.

And while we say economical, that isn’t to say these bots are any less beautiful or competitive! Hypershock also has a very impressive welded frame.

The benefit of this sort of frame is that it’s relatively cheap & easy to manufacture. The downside is that if a critical part of the frame becomes damaged, you might be required to throw the entire part away!

Bolted Chassis

Another common way to build up a chassis is to use several — usually thicker — machined aluminum pieces and screw them together at the joint. End Game is an example of this construction technique.

This sort of frame has the benefit of being able to add much more sophisticated features to the inside of the frame — for instance, End Game has specific features machined inside the inner rail of the bot, which allows them to shock mount their drive motors! The frame can also be repaired more easily if one particular part were to bend or break during a fight — replace one rail instead of the entire robot.

Billet Chassis

Now for my (completely biased) favorite type of frame, billet! Being the Cadillac of chassis construction, this sort of frame is machined from a single piece of stock — usually an aluminum or magnesium alloy. Arguably, this could be considered the strongest type of frame — there are no screw joints to break or welds to crack. There are also no limitations on the thickness of the plate — wherever you want material you can have it, and where you don’t, you don’t!

DUCK! is perhaps the most prominent example of a billet:

Though there are many more bots popping up recently with billets, including Glitch and Shatter:

While these frames are undoubtedly beautiful, they do have a few notable downsides. The biggest one is the difficulty in getting it manufactured. A piece of aluminum this big oftentimes doesn’t fit in your normal-sized Haas milling machine — you usually need something much bigger, which may be challenging to find.

The other disadvantage to billet is cost. For Bloodsport, the cost of a single billet chassis in the USA can be upwards of $10k. Overseas, it’s a bit cheaper at around $2.5k. Though if we were to go with the welded route like Biteforce, our frames would likely cost no more then $1k!

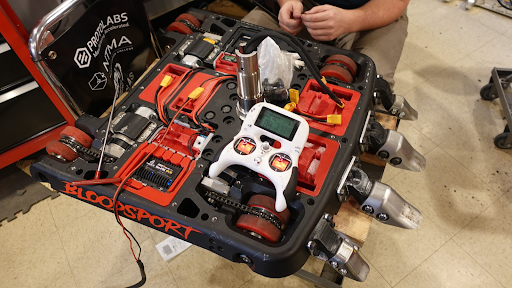

Though for us, the upsides outweigh the downsides. Bloodsport has been designed using a billet construction since its inception. The original goal of a billet was to simplify the construction process — because it’s a single piece, there were no parts to align, tolerance or otherwise worry about.

The original Bloodsport frame from Season 4:

This was revamped for Seasons 5 & 6:

And further optimized going into Season 7:

As you can see, the internals of Bloodsport is very precisely known before the robot ever hits manufacturing. There is no moving the batteries to the other side of the robot or moving motors around. This allows us to make the frame as small and stiff as physically possible, though we have to be extremely sure that everything is in the exact right spot in CAD. Otherwise, it might be a very expensive mistake to have them redone! Bloodsport’s billet chassis for season 7 was manufactured by our sponsor, Protolabs.

#deathtosilverboxes –Will Bales

As a BattleBots competitor, it’s important to recognize that Battlebots is entertainment and a show first. Many bots on the show are here, not because they are the best possible & most competitive design, but because they give the audience some variety! Bloodsport is no different here — we go through a lot of effort to try to make Bloodsport look as little as a silver box as possible. An angled edge of the chassis, smooth corners, nice filets all the way around, are all tricks not only to try to optimize the design and effectiveness of Bloodsport, but the looks as well — I hope it doesn’t look like just another box!